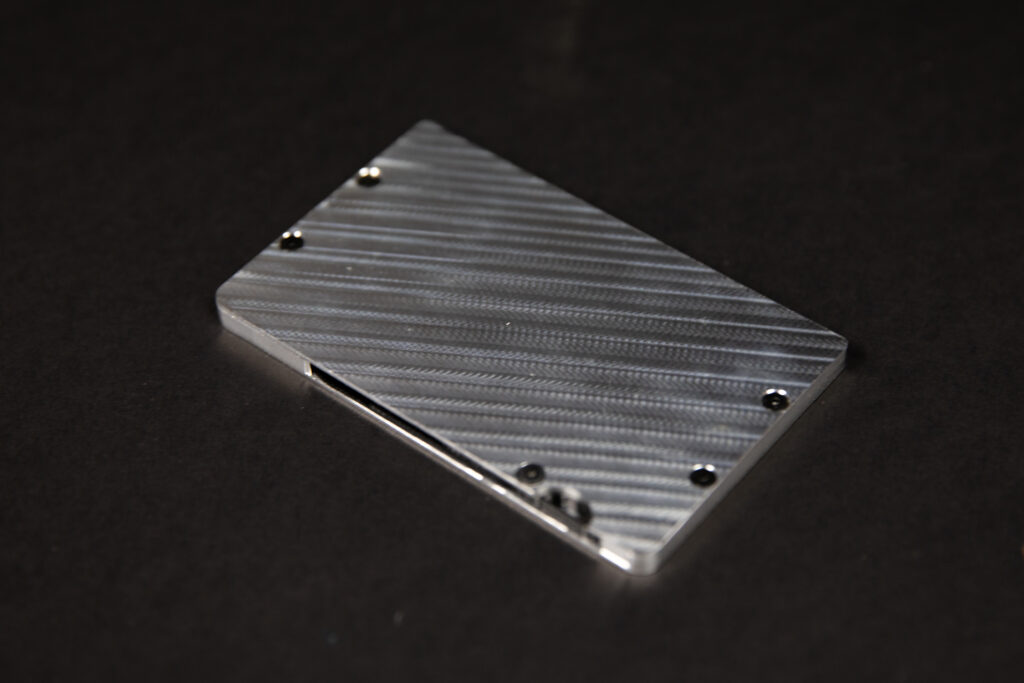

Minimalist Cascade Wallet

My apple wallet was falling apart for weeks, so I designed a relatively simple wallet which fits three cards and a few bills in Fusion360. I hated how most wallets that rely on friction required for all the cards to be taken to access a single card. With the wallet, there is a 3D printed lever that pivots on a 2-56 screw. The lever has staggered stages which pushes out the bottom card first then the middle then the top allowing for easy access of all cards.

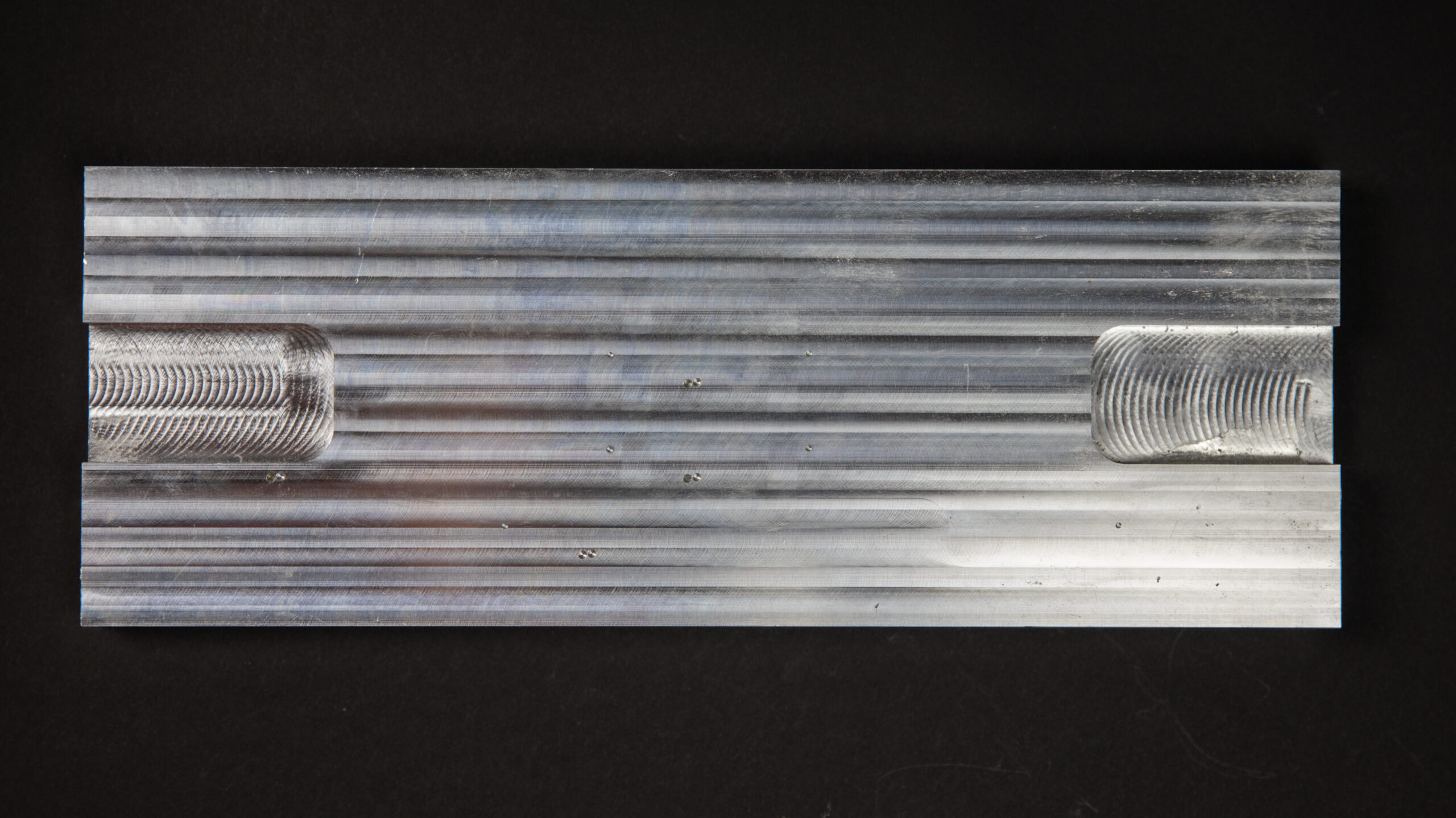

The wallet comes in under 1/4″ in thickness and is machined out of 6061 T6 Aluminum. Due to the thin nature of the raw stock for both the cover and body of the wallet, I used Super Glue workholding to keep the stock flat. The raw stock was work held to a custom machined fixture plate which had machined top and bottom faces ensuring parallelism and machined which allowed for the finished pieces to be gently pried off the fixture plate. The top and bottom visible faces of the wallet are treated to a 30 degree horizontal facing pass creating overlapping square end mill marks which when paired with light creates a 3D effect.

8 total wallets were made in the later half of 2024 for friends, family and some online orders. This project came out of a need for a new wallet and ended up consuming many late nights and school days making wallets for anyone who wanted one. Through this, I learned how to render models (not well at the time, don’t judge me too harshly), design for manufacturing and bring a concept to market.